What’s the deal with the semiconductor shortage?

We hear a lot about the shortage of semiconductors these days in the news, and the complaints are especially loud in the automotive sector. On top of that, many new students coming to campus this fall will find that there will be a shortage of laptops for many of them…. So what’s the deal? Why are we so short of semiconductor chips?

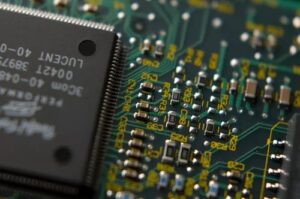

Actually, the semiconductor shortage has been going on for quite some time. It has gotten particularly bad, but it was definitely occurring prior to COVID. Demand for semiconductors has been driven by a significant and increased level of digitization of all products, including includes dishwashers, coffee makers, your thermostats, what have you. Everything now is becoming digitized and thus has semiconductors built into it. Recent reports suggest that in 2010 27% of vehicles relied on electronics that includes semiconductors. It was 40% by 2020 and it’s likely to be 45% by 2030. Demand for chips reached a peak in 2018, it dropped a little bit in 2019 and then it escalated again in 2020 when there was a massive demand for home electronics during the COVID pandemic.

The problem with capacity in chip making is that manufacturers are loath to invest in additional chip making capacity until they’re certain that there’s going to be the demand for it. Building a chip plant today can cost several billion dollars. And so chip manufacturers can only invest in capacity in large chunks – e.g. an entire facilities. And in the past, they’ve been burned because they invested in these facilities and then demand fell off and they were stuck with the investment that was not earning anything. So, there’s been a big lag in capital investment for chip production.

This has impacted all industries, but it’s been particularly bad for the automotive industry. When the pandemic hit, the automotive companies were immediately afraid that there would be a drop in demand for vehicles. Well, as we all know, demand spiked. But prior to that, the automotive companies had told the chip makers, we think demand for cars will drop with COVID< so we’re going to halt all our production orders with you. We don’t think we’re going to need them.

Big mistake. As we know, demand for cars went through the roof. So the car companies went back after and told chip producers, we we’ve made a mistake. We actually do need your chips. The problem is that capacity had already been taken up by other manufacturers, especially electronics manufacturers, and so the automotive companies had to get in line like everybody else, and they were at the back of the line. And they still are – which is why there’s been so many problems in the automotive sector for chips.

Another problem is the structure of the chip industry itself. One of the major bottlenecks is around the so-called logic chips that are produced by Qualcomm and Nvidia or Apple. These brands don’t actually own the fabrication plants, they outsource them to what are called foundries. These foundries are essentially contract chip makers, or contract manufacturers. About 91% of the contract chip production capacity is within Asia. About 50% of all foundries are located in Taiwan with one company, Taiwan Semiconductor Manufacturing Company (TSMC), and another 25% is Samsung, which is also produced in Korea. The American chip manufacturers like Intel and AMD have not traditionally been foundries. That’s starting to change. Intel recently unveiled a plan to set up its own $20 billion foundry in Columbus. Jason Miller and I conducted some analysis that shows that the Intel facility alone will only even cover less than 4% of the total demand for semiconductor chips.

In addition to the bottlenecks with the contract manufacturing foundries, you also had massive COVID outbreaks in Taiwan in June 2021 t. And also there were bottlenecks in the largest chip testing and packaging company. There’s one called King Yuan electronics, where they do all the testing, so that’s another bottleneck. And every supply chain student knows that bottlenecks cause disruptions to what was already an oversold supply chain. So while. the lead times for chips used to be two to three months, in many cases now, they’re more than a year. And it’s just taking an enormously long time, for companies to keep up with this demand for chips in the market.

Get used to it! It will be awhile before facilities can be built to make more chips!